Mistakes to Avoid for Choosing the Best Slab Stone Supplier

Your decision to select the optimal Slab Stone Supplier demands careful investigation because it shapes the quality of your products together with service reliability and investment return. Your selection of suppliers directly determines your project quality regardless of whether you handle massive commercial construction or residential renovation or outdoor design. People often rush their supplier decision without proper attention to crucial factors and this leads to avoidable issues and delays and dissatisfying results. In order to assist you choose a slab stone provider that will best meet your project’s demands, this article outlines eight typical blunders to avoid.

1.Neglecting to Research Supplier Reputation

Neglecting a supplier’s standing in the market might cause serious problems for your project. Spend some time researching possible providers in-depth by reading client testimonials, looking up industry rankings, and getting references from prior customers. Inquire specifically about their dispute resolution procedures, material quality consistency, and delivery timeliness. Go to internet discussion boards where homeowners and contractors share their experiences working with nearby vendors. As duration frequently denotes stability and dependability, pay attention to the supplier’s length of operation. Keep in mind that a provider with a stellar reputation for quality and service but somewhat higher costs usually offers greater value than a less expensive one with dubious business practices.

2.Focusing Solely on Price

Choosing a provider only based on the lowest estimate can frequently result in disappointment and unforeseen costs. Budgetary restrictions are crucial, but exceptionally cheap costs usually signify sacrifices in finishing standards, extraction techniques, or stone quality. Take into account the entire cost of ownership, including possible replacement expenses in the event that subpar materials fail too soon. Consistent hue, suitable density, and adequate finishing that lowers maintenance needs are all characteristics of high-quality stone. To find out what’s included, ask for thorough prices. Delivery, cutting, edging, and waste material collection can all have a big impact on the total cost. The most economical supplier maintains open business procedures and offers reasonable prices for products that are acquired responsibly. Keep in mind that making an initial investment in high-quality stone usually lowers ongoing costs and maintains the visual attractiveness of your project.

3.Failing to Inspect the Stone Selection Personally

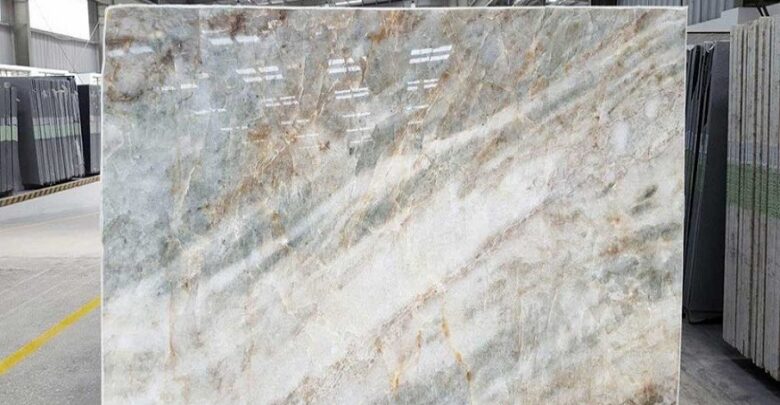

When choosing real stone, relying just on photos or catalog samples puts your project in serious danger. Every quarry produces stone materials that differ substantially from one another because each slab possesses unique pattern effects together with distinct color variations and mineral characteristics. Examine potential slabs personally by scheduling inspections which should happen in daylight conditions to reveal their authentic color schemes and patterns. Examine huge slabs from various perspectives to see how sunlight changes their look. Check for structural problems that might affect durability, such as cracks, soft patches, or uneven density. To guarantee a seamless integration, bring examples of other materials from your project, such as flooring, paint swatches, or cabinet samples. The most seasoned vendors encourage in-person material inspections before purchase and keep their slab yards neat and well-lit.

4.Disregarding Material Origin and Sourcing Practices

Your stone’s ethical status, environmental effect, and quality are all greatly impacted by its source. Reputable vendors keep thorough records on labor conditions, extraction techniques, and quarry locations. Destructive quarrying methods that irreversibly harm ecosystems may be used to obtain stone from areas with lax environmental rules. In a similar vein, certain areas may not have adequate labor laws, which may encourage unfair work practices. Inquire with suppliers about their sourcing practices and whether they visit the quarry to confirm conditions. Additionally, take transportation distance into account. Materials that are supplied locally tend to have smaller carbon footprints and boost local economies. In order to confirm responsible sourcing, suppliers who are dedicated to sustainable practices frequently take part in industry certification programs. By knowing this, you can make sure that your lovely stone doesn’t have any unintended social or environmental consequences.

5.Overlooking Inventory Management and Supply Consistency

Project delays and difficulties matching materials might result from a supplier’s inventory management procedures receiving insufficient attention. Expert suppliers have built partnerships with quarries to expedite special orders and maintain sufficient stock levels of popular commodities. To guarantee uniform hue over several deliveries, find out about the supplier’s reserve stock for major projects and the usual wait periods for the stone you have chosen. Ask them about their backup plans in case quarries temporarily stop producing a certain type of stone. Reputable vendors keep records and record lot numbers so that subsequent orders may be matched with the original supplies. This becomes particularly crucial for phased projects or possible future fixes. Usually, suppliers with advanced inventory management systems can offer accurate delivery dates that coincide with your building timetable, avoiding expensive delays.

6.Ignoring Technical Support and Expert Guidance

Undervaluing the importance of your supplier’s informed advice might result in poor material selection and issues with application. Staff members with in-depth technical understanding of material qualities, suitable applications, and maintenance needs are employed by superior stone providers. Important parameters for your intended usage, such as water absorption rates, freeze-thaw resistance, and slip resistance factors, should be easily discussed. Reputable vendors provide detailed technical information and advice on appropriate sealants and cleaning agents and adhesives which work well for different types of stone. The vendor needs to ask thorough questions about your project conditions including high temperatures and wetness along with heavy traffic patterns. Beyond the original sale, suppliers who provide installation workshops, maintenance manuals, or post-purchase assistance show their dedication to their customers’ success.

Conclusion

When choosing a Wall Cap Distributor, steer clear of these eight typical blunders to safeguard your money and guarantee project success. You may work with a supplier who genuinely improves the results of your project by giving reputation, quality, personal inspection, ethical sourcing, inventory management, technological know-how, logistical skills, and after-sale assistance first priority. Keep in mind that the correct supplier turns into an invaluable asset over the course of your project, offering not only supplies but also knowledge that enhances performance and long-lasting attractiveness.